Hardness Testing

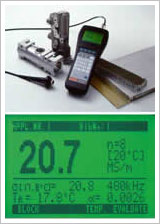

On-site hardness testing is carried out by means of a portable hardness-testing unit. This unit is capable of converting values such as Brinell, Vickers, Rockwell and Shaw. On-site hardness testing is required to compare the hardness values between the production weld metal, the parent metal, and Heat Affected Zone (HAZ) mainly after Post Weld Heat Treatment has been carried out. This is to ensure the hardness values are acceptable within each zone of the weld joint. Usually 3 spots are tested within each zone and an average reading is then qualified.

The advantage of on-site hardness testing is you are able to ensure that parameters have been keep for Welding and Post Weld Heat Treatment during both processes.