Ultrasonic Testing

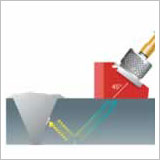

Ultrasonic Testing in industry uses sound waves the same way they are used in hospitals to check an unborn child still in the womb. When used in Industry, Ultrasonic Testing determines the quality of the internal structure of Weld Joints, Castings and various Materials for soundness and for detecting any internal flaws or defects. Using specially designed probes, sound waves are sent through the item being tested. Once these sound waves hit a defect or flaw within the body of the material, the sound waves then bounces back and the technician interprets the results on the Ultrasonic Testing machine’s viewing screen.

Ultrasonic Testing Machines are designed so the technician is able to size up the defect or discontinuity that has been detected. If the item being tested is free of defects or internal flaws, the sound waves pass right through without any interruptions allowing the technical to prove soundness of the item being tested.